eNews

Improving Plasma Cutting Quality – Part I

Developing a pre-flight†routine for operating a plasma cutter will prolong its life, as well as increase its efficiency and precision

Plasma cutting is easy to learn and use. In fact, it’s so easy that many users remove the unit from its packaging and go to work. However, that approach may not optimize the plasma cutter’s capabilities.

Before Starting

The first and most important step after purchasing the right plasma cutter is to read the owner’s manual, Don Keddell, training specialist at Miller Electric Mfg. Co., Appleton, WI, said.

Reading the owner’s manual is an important step and one that many users fail to take,†he said. It pays to take the time to read it thoroughly and get to know that particular plasma cutter. It contains important information about safety and getting the most from the plasma cutter.â€

The following information does not replace a thorough reading of the manual. Read the manual then keep it handy so all operators can reference it as needed.

Keddell suggests developing a preflight routine†for using a plasma cutter, starting from the back and working forward.

The Powers That Be

Check the power cord to make sure it’s in good condition and that it’s plugged into the correct type of primary power supply. Some units, such as those using Auto-line technology, can plug into any power supply from 208V to 575V. Other units require a specific voltage. It’s up to the user to make sure they are plugged into the correct power supply and any power selection switches have the correct setting.

Let it Flow

Check the air supply to make sure the correct air flow and pressure are entering the machine. The owner’s manual should contain the air requirements.

A Filter is Necessary

Dry air is important for plasma cutting and maximizes cutting capacity. Keddell recommends installation of an air filter and/or dryer on the machine, if it does not come equipped with one. Check, clean, and replace the filter and/or dryer in accordance with the manufacturer’s recommendations. It’s important to have some type of sealant on the connection to decrease the risk of an air pressure leak, Keddell said.

The Right Connections

Connect the torch, if it’s not already connected.

Snug as a Bug in a Rug

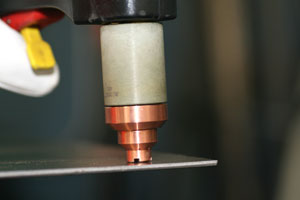

Make sure all of the consumables are in place and correct for the job, and that they are snug and secure. Do not over-tighten the cup; intermittent cutting will result if it is too tight.

Selection Time

If applicable, select the proper process. On some higher-output machines, a switch lets the user choose between cutting and gouging.

Go!

Turn the machine on.

Check it Out

Check the air setting. The PSI setting may have different settings for cutting and gouging. On some plasma cutters, the operator turns the amperage down to zero, which turns on the air flow and lets the operator set the correct pressure.

Set it Right

Set the output to the correct setting.

A Need to Connect

Check the ground connection to the work piece. Although plasma can cut through painted metal, it does require a solid connection on a clean part of the workpiece as close as practical to the work area.

A drag shield lets the user rest the torch on the work surface and maintains the proper standoff distance

Don’t be Shocked

Make sure all of the safety gear is in place. The owner’s manual will have more details, but in general, the same type of protective gear is needed as when welding. If the table is wet and a user lays their bare arm on it, they can become part of the circuit and receive a shock. Welding leathers, along with proper gloves and eye protection, should be worn. Usually a #5 shade is the minimum eye protection with other shades required depending on amperage. Keddell recommends a face shield, too.

Try a First Draft

Make a sample cut on the same type of material as the workpiece to check settings and travel speed.

Practice Makes Perfect

It is difficult to stop clean and continue a long cut. Rehearse the cut beforehand to make sure there is adequate freedom of movement to make one continuous cut.

While it may be easy to unpack a plasma cutter and begin cutting, take the time to get familiar with its proper operation. Implementing these steps will help use the machine safely, properly, and efficiently.

Want more information? Click below.

Miller Electric Mfg. Co.

Please rate this article:

Very interesting, with information I can use

Interesting, with information I may use

Interesting, but not applicable to my operation

Not interesting or inaccurate

Comments: